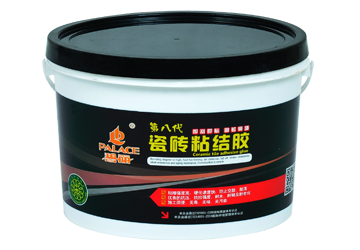

Ceramic Tile Adhesive

Ceramic tile often falls off in stickup process under the influence of construction condition, ambient temperature, adhesive material, especially of ceramic tile density and moisture absorption. In allusion to the problem that ceramic tile tends to fall off during, PALACE successfully developed the 8th generation of ceramic tile Adhesive (scratching and pasting), which solved the problem that materials of low moisture absorption such as vitrified tiles, archaized tiles, microlite and marble are difficult to be fixed, and mainly used with cement mortar, that is, after wiping and scraping a layer on the back of the tile, tile can be fixed according to the ordinary wet stickup method with cement mortar without waiting. It is convenient, simple and quick for construction, and the effect is good. Compared with other similar products on the market, it saves a lot of construction time.

Construction technology:

1. Scrape the Adhesive directly and evenly onto the pretreated base surface;

2. Immediately apply cement mortar for stickup before the Adhesive dries.

Range of application:

1. Used for interface pretreatment and frost prevention of vitrified tiles, archaized tiles, microlite and marble and granite with low moisture absorption.

2. Widely used for interface enhancement in building and bridge reinforcement, waterproof, moisture-proof and other fields.

3. Used for interface treatment of new and old mortar.

Matters needing attention

1. It is prohibited to add other diluents into the adhesive;

2. Cover up the unused adhesive to prevent it from drying; dry adhesives shall not be used;

3. It reaches the optimal bond strength 15 days after under 20℃, and 7 days after above 20℃.